Hull #030 - Ohana

Image Gallery

Quick Facts

- Model: Cruising

- Year Built: 1968

- Hull #: 30

- Vessel Name: Ohana

- Owner Name: Chip Rossi

- E-mail: sirsurf13@gmail.com

- Hailing Port: North Shore of Long Island, Centerport, NY

Sailboat History

2020 – [Chip Rossi] got this 27 from David Berke of Islip NY. He had not used it for some time and was in pretty bad shape. However sails were practically brand new. So I spent 2 years restoring to best of my abilities. She’s not perfect, but is being sailed again. David had resurrected her previously and renamed her “Second Wind”. While stripping off some old hull paint I found the name Iron Dog (I think). I decided to rename Ohana.

October 22, 2015 – The previous owner sailed her out of Southhold NY Long Island. Last name was Second Wind, I plan on changing after I complete an upgrade to her. I have the outboard version in aft lazarette. Attached are some pictures of the work in progress.

August 23, 2015 – About a month ago I acquired a Bristol 27 from David Burke. At this point not looking to make her blue water boat, but she is cosmetically a mess, and has some minor structural issues that need to be addressed.

At this point I have stripped all of the teak and most hardware as I am prepping to paint deck. Ultimately will be based in Centerport NY and South Jamesport NY. Hopefully am going to create a google site to chronicle my restoration. I hope to have her sailing by next summer.

[Here’s a picture of the boat just after it had moved to Chip’s backyard for renovation:]

Owner Comments

June 5, 2018 – This past winter and spring I have put a lot of time and effort into Ohana Hull #30, which I have sent info on. It was in terrible shape, but I restored her to the point that she attracts a good deal of attention. Not my desired goal, but nice, I just want a solid seaworthy boat for coastal cruising east coast. Anyway, I am a teacher, before that worked for 10 years in a boatyard and marina on Long Island, Coneys Marine. I also run a waterfront program for a local camp during summers which will not be operating this summer. So, I have been working there on weekends rigging and running launch service to help supplement income for my Summer that normally helps to pay for my “hobby” of owning a boat. They have been great at welcoming me back in to the fold of their business, and I think I have a lot to offer them, so it works well on both ends. But they took this great video and posted on youtube that I thought you could use on your site to motivate and inspire other Bristol 27 owners. As I said to my wife, they did such a nice job. it looks way better on video than reality! But I know every strength and every weakness of this boat hands down, since restore in 2015.

August 12, 2017 – Ohana is out sailing:

June 21, 2017 – Hull 030 Back in. It isn’t perfect, but really wanted to be able to sail her this summer, so how fitting to launch on the Summer Solstice. I have renamed her, with of course proper offerings to Neptune and Poseiden, “Ohana”. Ohana is Hawaiian for family, and also from the movie Lilo and Stitch which was always one of my kids favorite movies, and now I can sail with them. Will continue to work on her interior while in the water this Summer and Fall. She will be sailing out of Centerport, on the North Shore of Long Island.

[Here’s a picture of the boat back in the water:]

April 10, 2017 – My old coamings were pretty shot, tried using some rot doctor injection epoxy, but just was not satisfied that they would hold up and look decent. So, I fabricated new ones out of sapele, African Mahogany wood. They are about 1/4 inch thicker than original, so bending them to fit cockpit contours was nerve wracking. Used a Harbor Freight pick up bed container bar to bend to shape, and prayed (a lot!). Bedded with 3M 4200, some adhesion, but NOT permanent like 5200 just in case I need to remove in future. Used 3 coats of cetol natural teak to protect, more orange tint than I desired, but do not want to spend my life tending to varnish, as much as I love the look.

October 29, 2016 – Boat did not go in this Summer as I had hoped but progress still continues as I get set to cover her for the Long Island winter. Included are some updated pictures.

Toe rails were stripped of old varnish and sanded and mostly salvaged, although some areas were shot and had to be replaced. Hope to reinstall the toe rails before I cover. I plan on countersinking every hole and using machine screws to bold entire rail down. Going to be a PIA, but I have done this much work already, and don’t like the look or feel of sharp goop covered wood screws entering the cabin.

I have also been using butyl tape to bed hardware. So far seems to work great for cleats, hatch hinges etc.

Backing plates made from G10 FR4 cloth reinforced epoxy. Strong, won’t absorb water, and pretty easy to work with. I figured it also won’t react with stainless bolts.

Hull and deck are now painted. The paint job is not the greatest, was simply rolled on hull. On deck used Interlux Perfection and Kiwigrip nonskid. Hull was Total Boat one part polyurethane. I went with the one part poly after having painted the deck with the 2 part poly, that was a PIA to work with. Would dissolve every roller I tried. Discovered the 1 part poly on the hull did same thing….oh well. After using a variety of “Marine” rollers supposedly designed to be used with Polyurethane paints and epoxies, the one that ultimately worked the best was a 6 inch hotdog roller from Home Depot! Go figure. Looks good enough from 10 feet away.

May 23, 2015 – Slow going, but I thought I would share some progress albeit, not as much as wanted. My goal/desire is to just get her splashed by mid summer here in Long Island NY. Not going to be perfect, but that’s ok.

So first pics are of portlight frames that I have bedded new plexiglass in place using Silpruf SCS2000. I hope that setting them into aluminum frames first will make it easier when I try to re-install them back in the boat. Less moving parts hold on to. We shall see how that goes.

Just installed new portlights, which went better than expected. Frames were ok, but drilled out old threads, and through bolted. After reading many posts about how to hold plexiglass in place while matching up frames etc. I decided to first bed the plexiglass into one recessed frame, let set for a couple of days and then come back run a bead of scs2000 sealant around opening, and some on screws and put in place. Worked great I think. I used bronze tinted plexiglass, was a bit nervous about how it might look. But turned out pretty nice looking I think.

Also, discovered many layers of old paint an various odd fillers etc. under the paint. At first I wet sanded some gelcoat which came out pretty nice, but then I realized it was too far gone all around. She will be getting some new hull paint in addition to re-painting the decks, which were completely shot.

Most of core is okay, one bad area in cockpit by companionway, was able to drill holes and inject thickened epoxy, seems to have solidified it. Another damaged hole in deck, I grinded back to dry core and then rebuilt and patched with fiberglass.

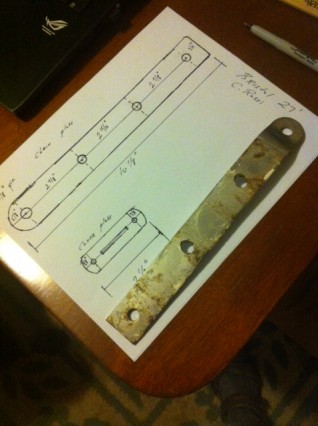

October 26, 2015 – Had one severely bent chain plate, checked others and found most of the bolt holes slightly out of round, and most were twisted to some degree. The two in the forward lowers where the worst. Decided to replace and upgrade all for peace of mind. Ordered from Texas chain plate express and they were done in less than one week! 316 stainless with cover plates. Increased thickness from 1/8 inch to 1/4 inch. New ones are 1 1/4 inch wide. Total cost $440, I believe worth every penny. Others may disagree, but I am happy with upgrade. Will install after interior and exterior refurbish.

Comment Form