Hose, Fittings & Pipe

Image Gallery

Project Logs

December 29, 2011

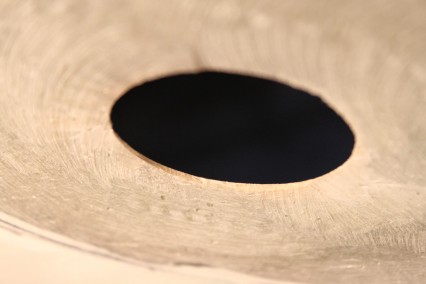

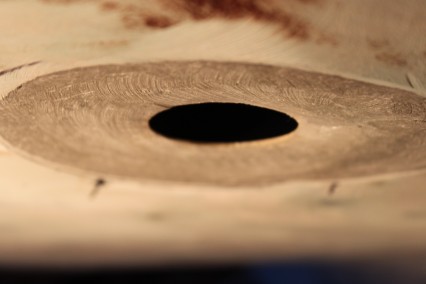

Recently, I routed 2″ exhaust hose out below the cockpit, through the lazarette bulkhead, through a lazarette “splitter” bulkhead and through the lazarette locker sole to test to see if the 2″ hose would be able to make the required bend. Happily, I found that the exhaust line ran fine and would have the required loop near the transom where the exhaust exits. Here’s an image of the hose looping successfully in the lazarette:

July 14, 2011

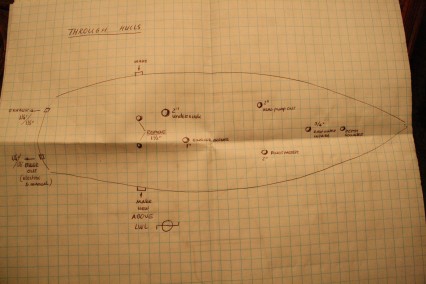

Upon completion, my sailboat will only have 2 through-hulls: one for the engine raw-water intake and one for the sink. I’ve glassed in a backing plate for the raw-water seacock while constructing the bilge, however I’m not entirely sure if it will work or not. I’ll probably need to make a decision as to using the already glassed fiberglassed backing plate or installing a new plate here in the next couple of weeks.

Research

- When you have bends in your hose you need the wire-reinforced type to prevent kinking and collapse.I don’t know what “soft” exhaust hose is, but in general exhaust hoses are called “hardwall” because of the makeup of the hose itself, with or without wire. Whatever you use, be sure it’s marked as “wet exhaust hose” (the exact markings vary brand to brand) and you’re ensured of the correct product. (http://www.plasticclassicforum.com/forum)

- The most bendable reinforced hardwall exhaust hose is the corrugated type, such as this Shieldsaust- C. The corrugations make bending almost easy.

Fittings

- Forespar sells a motor well drain that allows through bulkhead draining. This may be useful for through bulkheads. (http://www.forespar.com/products/boat-marine-plumbing-motor-well-drain.shtml)

- It’s not uncommon to use one pump for two compartments, such as one fresh water pump for two tanks or a bilge pump for two separate parts of the bilge or cabin. A diverter valve allows you to close and open the passage to each compartment. Similarly, a Y fitting enables two pumps to discharge through one outlet, which waves on hose and thru-hulls. (Upgrading the Cruising Sailboat, p. 108)

- Diverter Valve – use this for rain collection into jerry cans to check water for taste. Whale pumps makes a “diverter valve” # 423780

- When connecting hose to connectors (sea cocks, pumps, sink drains, etc. use a pipe sealant on the connector to ensure a watertight seal (Upgrading the Cruising Sailboat, p. 108)

- double reverse clamp everything (http://www.cruisersforum.com/forums/)

- At the end of the day, the fewer seacocks, the better I like it. (Cruising Handbook, p. 228)

- UL Standard 1121 Marine Through-Hull Fittings and Sea-Valves: Materials – The components of a through-hull fitting or sea valve shall be formed of galvanically compatible materials having the strength and resistance to corrosion necessary to withstand intended and abnormal use to which they are likely to be subjected.A part made of drawn brass or machined from brass rod containing more than 15 percent zinc shall be subjected to the 10-Day Moist Ammonia-Air Stress Cracking Test (Section 19). After being tested, a brass part containing more than 15 percent zinc shall show no evidence of cracking or delamination when examined using 25X magnification. (http://www.cruisersforum.com/forums/f115/home-depot-plumbing-fittings-just-bad-or-really-bad-19659-2.html)

- ABYC Standard H-27 Seacocks, Thru-hull Connections, and Drain Plugs – All materials shall be galvanically compatible and resist degradation to salt water, petroleum products, UV light, ozone, cleaning components likely to be encountered, marine growth, and the effects of heat aging. Copper-based alloys shall meet the requirements of the 10 Day Moist Ammonia Air Stress Cracking Test in UL 1185, Portable Marine Fuel Tanks (Note: This reference appears to be an error and should be UL Standard 1121). (http://www.cruisersforum.com/forums/f115/home-depot-plumbing-fittings-just-bad-or-really-bad-19659-2.html)

- All valves should have a lever-type handle that operates through 90 degrees this way you can see immediately if the valve is opened or closed. (Cruising Handbook, p. 226)

- Check valves are another problem in bilge pumping applications….the response [to back flooding] is often to fit a check valve in the line; however, not only do check valves create a resistance equal to that of many feet of pipe or hose, they also are prone to both plugging (in which case the pump is inoperative) and getting jammed in the open position (in which they will not stop water from siphoning into the boat). (Cruising Handbook, p. 221)

- Example of thru-hulls for engine/bilge – (1) 2″ hose for exhaust (1) 3/4″ hose for Jabsco diaphragm pump (1) 1.5″ hose for Whale Gusher manual pump (1) 1.5″ hose for Rule 3700 backup pump…preferably a set that has similar diameters when measuring the width of their flanges in order to keep things looking as tidy and symmetrical as possible. That would still leave me with finding a place to discharge the 3/4″ hose of the Jabsco pump (http://www.plasticclassicforum.com/forum/)

- A better approach to siphon prevention is to dispense with the check valve, raise the discharge hose from the pump above the highest possible heeled waterline level, and fit a siphon break at the top of the loop. The extra static head has to be factored into any bilge-pump flow-rate calculations, but it will be substantially less than the head pressure created by a check valve. The extent to which the hose must be raised above the waterline can be minimized by discharging it overboard on the centerline at the stern (rather than over the side), but this may result in unacceptably long hose runs. (Cruising Handbook, p. 221)

- Metal components must be cast from high-quality bronze (Cruising Handbook, p. 226)

- Any fasteners used to retain a bronze seacock must be of the same or a better quality bronze. If they are not, galvanic corrosion is likely to eat up the fasteners. (Cruising Handbook, p. 226)

- …need some kind of backing block, faired to the shape of the hull, and providing a level surface on its inboard side on which to seat the retaining nut or seacock. This helps spread to a larger area of the hull the inevitable shocks, stresses, and vibrations experienced by the fitting…Make sure all seacocks are readily accessible. (Cruising Handbook, p. 227)

- For research regarding fittings for tanks, please visit the ‘Tankage‘ project page.

Hose – Bilge, Engine & Through Hull

- Larger hose reduces back pressure, which is good in general, but 1.5″ hose is adequate for that small engine. Smaller hose and smaller fittings tend to be less expensive, so that might be a good reason to choose that since you’re given the option. There’s no real pitfall to using the larger 2″ hose, other than its additional cost and the additional cost of fittings (through hulls, waterlifts, etc.) to accommodate it. ….HOWEVER…Considering that the manufacturer says 1.5″ or 2″ I would say whichever suits the other fittings in the system.A larger diameter hose means less constriction and better breathing for the engine.A larger diameter also means the exhaust gasses don’t have to move as fast so they transmit a lot more heat on to the exhaust piping on their way out which increases corrosion and wears the exhaust system out faster. Exhaust piping is a consumable part. It doesn’t live forever.The engineers that design the motor look for a balance between these two outcomes.For the size of motor we are talking about I would have to think 1.5″ is plenty big enough . My Honda Civic motor is very efficient with 1.5″… AND…It’s my understanding that oversized pipe actually decreases engine efficiency, as the engine requires a certain amount of back pressure to run properly.My Yanmar 2GMF 13 hp exhaust manifold outlet is only about 1″ diameter (if my memory is correct) and uses 1 1/4″ pipe for the riser. From the end of the riser to the Vetus WLOCKL40R muffler I used 1 1/2″ ID hose (that can be persuaded over the 40mm muffler inlet using a bit of rubber lube), and 1 1/2″ hose to the riser at the transom…..FUTHERMORE…The diameter of the exhaust for internal combustion engines is not related to the “back pressure” so much as it is to the velocity of the exhaust gasses. The engineering gets pretty complex but the concept is that a moving column of any fluid has inertia and the quicker you move it up to a point the more it tries to keep moving, and the more it will create negative pressures between the “pulses” of the cylinders firing, in essence trying to ‘suck’ the exhaust out of the cylinders when the next exhaust stroke comes. Having a large diameter passage allows the gasses mixed with water to meander along, allowing the water to “puddle” and get blown out when the puddle gets too large. A smaller diameter passage keeps the gasses moving briskly and causes the cooling water to exist pretty much as spray, (except in the trap) which makes it move better, and the spray also destroys the accoustic qualities of the tube better, making it quieter. There is no benefit going larger than the exhaust fitting on the engine.You can however restrict too much, but that is obvious. (http://www.plasticclassicforum.com/forum)

- Exhaust hose requires a heavy-duty, fabric-reinfoced construction. Until recently, there were no standards governing these hoses, but quality hose was invariably labeled “Type Certified Marine Exhaust Hose” or something similar….The [new] standard requires that the hose be able to withstand a total loss of cooling water for two minutes with the engine running at full power, and still not suffer a loss of integrity – a very tough test. Any hose that meets the J2006 standard (it is written on the hose itself) can be counted on to give good service. (Cruising Handbook, p. 229)

- Exhaust hose comes with or without wire reinforcement. In the former case, it is known as hardwall; in the latter, softwall. Most manufacturers recommend that hose runs longer than 4 – 6 times the inside diameter of the hose (most exhaust hoses), or those with relatively tight curves, be wire-reinforced for added support. The objective is to prevent hose kinking on bends, sagging on long horizontal runs, and panting (pulsing) from the constant pressure changes that occur in an exhaust. If a hose is adequately supported and if tight bends are avoided, the reinforcement can be avoided; however, the support is critical. The hose should never span open spaces or be hung from deck beams because the painting will cause chafe at the supports or hangers. If necessary, the hose should be given a bed to sit on. (Cruising Handbook, p. 229)

- For exhaust applications, radiator hose will not do. You need exhaust hose. Exhaust hose is similar in construction to radiator hose. Actually you may find exhaust hose without wire reinforcing – sort of a high-temperature heater hose – but soft-wall hose is a bad idea for exhaust. Hard-wall hose will not collapse in bends or be crushed by shifting contents in a locker it passes through. Exhaust hose is constructed of synthetic rubber and should carry an SAE J2006 designation, which will be stenciled right on the hose. This tells you the hose can withstand a temperature of 1,000F for at least 2 1/2 minutes – hopefully enough time for you to notice the change in exhaust note, or the heat gauge needle climbing toward the red, and shut down the engine. The best exhaust hose, like the best radiator hoses, is constructed of silicone and can carry a continuous temperature rating of up to 500F, almost insuring that other consequences of no cooling water flow will preempt exhaust hose damage. A hose supplier may call all high-temperature tolerant hoses (steam hose), but be sure that what you buy for exhaust use is also petrochemical resistant.

- Before you replace exhaust hose, consult the manual for your engine to see what diameter is specified. New engines are too often fitted to old and undersized exhaust plumbing to the detriment of the engine. Exhaust hose can never be too big, only too small. (This Old Boat, p. 315)

- Radiator Hose – If you are sucking fluid through a hose rather than pushing it through, blockage on the suction side can cause heater hose to collapse like a straw in a thick shake. Radiator hose corrects this flaw by constructing the hose around a wire helix – like incorporating a stretched coil spring as the center ply. Just as the inelastic woven ply in a heater hose prevents it from expanding when subjected to heat pressure, the helical wire in radiator hose prevents it from collapsing when subjected to suction. The reinforcing wire also will prevent the hose from kinking when it is bent. Better radiator hose, also called wire-reinforced or hard-wall hose, also has a woven ply or two to restrict expansion. Wire-reinforced hose is your only choice for hoses on the suction side of both the coolant and the raw water plumbing for your engine or generator. Use hard-wall hose on the suction side of a deck-wash pump or a raw-water pump for refrigeration or air conditioning. Also use only hard-wall hose for any run that requires more than a gentle bend from one end to the other. Here’s a tip: if your plumbing requires a sharp bend in a water hose, a trip to an auto parts store…can often turn up a hard-wall hose with a molded bend that can be adapted to your needs by shortening one or both ends. Standard 1 1/2″ radiator hose is an excellent choice for hoses connecting to 1 1/2″ through-hull fittings – cockpit drains, high-capacity bilge pump hose, even head discharge lines. (This Old Boat, p. 314 -5)

- Hoses connected to through-hull fittings need first and foremost to be tough. Where the hose is part of the engine cooling system, heat resistance also will be important. Automotive heater hose satisfies both requirements. Tire-like construction with a center ply of woven nylon or rayon makes the hose strong and durable, and the “heater” designation means it is designed for high-temperature use. The rubber compound is usually ethylene propylene diene monomer (EPDM), but a big hose supplier will also have silicone rubber heater hose, which has about 4 times the heat tolerance and twice the life expectancy. Silicone heater hose is more expensive, but it is your best choice for most raw-water and cooling water hoses, and I like it’s durability for through-hull connections. (This Old Boat, p. 314)

- The most common size about is 3/4″ ID. Where flow rate is not compromised, standardizing as many fittings as possible to one size will allow you to limit your emergency spare to a single length of hose (or to borrow a temporary replacement from a less vital application). (This Old Boat, p. 314)

- To assist in preventing clogging, the end of the hose in the bilge should be fitted with a strum box or strainer. Many types are available. But be wary that even strainers can be sealed by a flat object such as a piece of paper. in fact, Ive had more clogging troubles with strainers than without them. With centrifugal pumps, strainers are probably important, but diaphragm pumps can pass some debris. Another option is to bend a heavy piece of wire or rod over the opening to prevent an object from pressing up flat against the opening. (Upgrading the Cruising Sailboat, p. 98)

- To minimize friction, hoses should have a smooth interior wall. Many of the most popular bilge pumps on the market have a 1 ⅛” out-side diameter discharge nipple…the only hoses manufactured to fit this size nipple are corrugated hoses, some of which have a smooth internal bore but many of which do not. Internal corrugations in a hose wall significantly increase the head pressure created by a given length of hose and, therefore, should be avoided. In any case, such hoses are often extremely thin walled and, as a result, are easily damaged….When pump nipple size gets about 1 ⅛”, any high-quality smooth-bore hose can be used. (Cruising Handbook, p. 220 – 1)

- Keep all hoses as short and as straight as possible..use the largest-diameter hose feasible on the discharge side. (Cruising Handbook, p. 224)

- The turbulence caused by the ridged interior decreases the flow rate through this type of hose as much as 30% compared to smooth bore hose….Do not plumb your bilge pump(s) with hose with a corrugated interior. (This Old Boat, p. 315)

- Below the waterline, including on raw-water circuits, I believe in using heavy-duty, fabric-reinforced hose (often made to comply with SAE J2006). It should be used for cockpit drains, sink drains, toilet suction lines, and associated applications…Remember that anything attached to a through-hull is an extension of the hull; its integrity should be as close as possible to that of the hull. (Cruising Handbook, p. 229 – 30)

- To pass a hose through a bulkhead or piece of cabinetry, drill a hole large than the hose with a brace and bit or hoe saw. When the pilot bit pokes through, go to the other side and finish the hole….cut a 6” length of larger diameter hose, slit one side, and slide it over the hose. In neat installations, all hoses are restrained with clamps and screwed to the undersides of furniture. (Upgrading the Cruising Sailboat, p. 92)

- ABYC – 33CFR 183.558 requires the use of hose meeting, and marked as such, the requirements of USCG Type A-1…but 33CFR 183.500-.599 pertains specifically to gasoline fuel systems, not diesel….33 CFR 183.540 (e) requires that any fuel hose meeeting the ratings of USCG Type A-1, A-2, B-1, or B-2 be clearly identified as such on the hose itself. (http://www.plasticclassicforum.com/forum)

- My advice is to use commonly-available hose meeting, and marked as meeting, the requirements for USCG Type A-1 for all parts of the fuel supply and return system. This meets the standards of ABYC H-33, which is a typically a smart and prudent course–and will also satisfy those who use these standards to determine insurability and general safety. None of this means that one cannot use, for diesel fuel systems, a hose that exceeds all applicable standards and requirements even if it’s not marked in a manner applicable to recreational boating. But since these other hoses will not be marked in a recognizable and easily identifiable manner, it will at a minimum tend to cause confusion at some future inspection, regardless of how suitable the hose truly is. One has to consider this sort of thing when making outfitting choices. How much hassle is a non-conforming hose worth? Finally, however worthy hose meeting standard SAW J1942 is, note that it must use specific hydraulic hose fittings on the ends in order to meet the standards. That’s all well and good as long as you use the proper fittings.It sure seems easier to just use type A-1 fuel hose. (http://www.plasticclassicforum.com/forum)

- your fuel line should be copper or the best quality aviation hose. This hose is of thick walled rubber with mesh reinforcing that will stand great pressure. (From a Bare Hull, p. 283)

- …based on the fire resistance of a hose and it’s permeability…Hoses that pass the most stringent test are classified as Type A; hoses with slightly less fire resistance are classified as Class 2. We end up with four classes of hose referenced in the USCG regulations….The regulations state that for inboard gasoline engines and inboard/outboards, any hose used for a fuel line must be clasfified as Type A1. Vent or fill lines have to be Type A1 or A2. Similar standards are in place for diesel fuel lines, except that the fill and vent lines can be type B1 or B2. (Cruising Handbook, p. 230)

- All you need to know about fuel hoses is that they bear an A or B rating for fire resistance and a 1 or 2 rating for permeability. An A-rated hose must resist a flame for at least 2 1/2 minutes; B-rated hose doesn’t have this requirement. Use only A1 fuel hose on your boat, whether for gasoline or diesel. Because the tank-fill line carries fuel but does not normally contain it, you might use the less permeable A2 hose here, but it is not hard to imagine fuel standing in this hose – the hose has a a sag, you leave the tank topped off in the off-season, or you are sailing on one tank for several days. You won’t be wrong using A1 hose for all lines carrying fuel. If the A1 (or A2) rating is not printed right on the hose, it is not an approved fuel hose. This type of hose is usually constructed from nitrile-butadiene rubber (NBR), a synthetic that gives the hose excellent flexibility and chemical resistance. (This Old Boat, p. 316)

- Special hoses are also required for oil or gas lines. Hot oil is especially hard on hoses, and any flexible oil lines should be checked regularly. Replacement hose must be designated for this use. Hydraulic lines must be rated for the pressures of the system they are part of. (This Old Boat, p. 315)

Hose – Grey & Waste Water

- Also use odor safe hose for vent (source offline)

- With odor-removing filter media, the vent filter stops odors from escaping the holding tank vent. Keeps boats smelling clean and pleasant. Each cartridge is good for an entire season and is easily replaced. (http://www.marinesan.com/category_s/95.htm)

- A diptube discharge allows for removal of waste from the top of the holding tank, rather than near the bottom of the tank. This feature greatly reduces the opportunities for stagnant sewage to sit in tank discharge lines – a main cause of odor permeation and hose failure. (http://www.marinesan.com/category_s/95.htm)

- Installations of sinks on boats do not have a water loop to prevent smells, which means if grey and black water is together in one tank, odours can escape straight from the tank up through the sink plughole. (http://www.boatwide.es/english/blackandgrey.htm)

- I used mostly 1 1/2 heavy wall grey PVC for most of the runs.The tank is from FG……about 80 gallons, it was added to the boat before I bought her…it was a fuel tank for cabin heater.I made up a PVC manifold for the inlets to go into tank through a single opening and a manifold on the single outlet with valves so I can select between a macerator pump (over the side) or to the deck fitting for dock pump out….Remember that you need to have a gas trap between the tank and the inlets…this can be done at the locker drains, but you may be better off having a single trap at the tank inlet manifold. (E-mail from James from Cruiser Forums)

- Even some heavy-duty hoses are minutely porous and, in time, will emit foul odors…Special impermeable hoses are required (usually labeled “Sanitation Hose”), and only the best (and most expensive!) should be used. When installing sanitation hoses, low spots that retain effluent should be avoided….Whatever hose is used for sanitation purposes, it should have a smooth wall on the inside, which minimizes the chance of clogging. (Cruising Handbook, p. 230)

- The more vertical the hose, the less odor will be a problem….avoid flat hose runs – or worse still, a sag… (This Old Boat, p. 316)

Hose – Water

- All fresh water plumbing in the boat can be taken care of by easy to buy, easy to bend, easy to use, and easy to mend ½” clear plastic FDA approved hose. (From a Bare Hull, p. 284)

- If you plumb your freshwater system with hose, use nontoxic clear vinyl hose. Be sure it is FDA approved for potable water systems. You can use unreinforced hose for plumbing hand and foot pumps, but for a pressurized water system the hose must be reinforced to prevent it from expanding like a balloon. Any hose that will cary hot water also must be reinforced. Because the cost difference per foot is pennies, I buy only reinforced hose, and I think I am rewarded with longer hose life. Reinforced clear hose is easily identified by the crisscross of braided polyester threads for the hose wall. (This Old Boat, p. 315)

- For any line that carries seawater, especially the head inlet or a galley saltwater supply line, clear vinyl hose stinks. This is not a value judgment; it really stinks….the light passing through the hose will encourage all manner of marine life to set up housekeeping inside the hose. The colony may go unnoticed as long as the line gets daily use, but if you leave the boat for a few days, much of the marine life dies in the stagnant water. (This Old Boat, p. 315)

- Algae can also become a problem in freshwater hose, especially if the water is stale and stagnant. Boats that see only weekend use are likely to see their clear vinyl hose take on a green tint. Allowing a bleach solution to sit for an hour or so in the hose kills the algae but does not remove it. Clear water hose on weekend boats is likely to need cleaning annually by disconnecting the hose and pushing or pulling a detergent-and-bleach soaked rag through it, perhaps repeatedly. If after you flush the cleaned hose with a blast of water (from a dock hose) the interior is shiny and/or feels waxy, put the hose back in service. A rough interior can harbor bacteria, dictating hose replacement. (This Old Boat, p. 315)

- A freshwater system plumbed with copper is definitely top-drawer, but copper tubing is relatively expensive and the fittings to join the tubing to other components add additional expense and complications, with both compression fittings and threaded connectors haing an annoying tendency to leak. Cold-weather sailors tell me copper also has a propensity to fracture in freezing temperatures. (This Old Boat, p. 316)

- Yet another problem with rigid piping is that many plumbing component for boats are manufactured with hose fittings. Such fixtures can only be installed in a rigid-pipe system with hose-to-pipe adapters. If you are forced by design to have some hose in the system, why not all hose? Clear vinyl hose may not have the class of copper plumbing but it excels in value and ease of installation. As for life expectancy, I have seen vinyl hoses deliver 30 years of trouble free service. (This Old Boat, p. 317)

- Copper, brass, and PVC are occasionally seen on older boats, but today the only real choice is vinyl. Most plumbing can be accomplished with various sizes of non-toxic clear vinyl hose…clear vinyl hose is easy to work with and can be routed just about anywhere. (Upgrading the Cruising Sailboat, p. 92)

- Vinyl hose should fit snugly, but it doesn’t like being stretched much. (Upgrading the Cruising Sailboat, p. 108)

Pipe – PVC

- Plasticizers – Plasticizers are generally clear, organic, liquid materials that are added to PVC formulation to obtain a flexible film to enhance both processability and serviceability of the end product. Plasticizers are very compatible with PVC resin and become an integral permanent part of the film matrix. Generally higher molecular weight plasticizers used in a variety of product applications including PVC geomembranes and medical bags, have significantly improved plasticizer loss rates over lower molecular weight plasticizers used in low end products such as shower curtains, book binding, etc. (http://www.morganscloud.com/2008/05/18/pvc-pipe/)

- Pro’s – PVC pipe is dirt cheap, variety – even a small corner hardware store has enough PVC plumbing fittings in stock for most jobs and the bounty in the bins of a large building supply store will let you build almost anything, Flexibility. No, it does not bend, or at least not much, but the amazing variety of PVC pipe fittings allows you to solve some very vexing problems surprisingly easily, Fast Assembly. With a little practice and a pipe cutter you can assemble a plumbing system amazingly quickly using PVC pipe. (You can cut the pipe with a saw, but it is time consuming and messy.) Long Lasting. Even good quality hose only seems to last five years or so, but PVC pipe will last decades. Impervious to Most Chemicals. You can flush a PVC pipe system out with muriatic (hydrochloric) acid; the quickest and, as far as I know, only effective way to get rid of the scale that builds up in head discharge lines. Don’t try that with hose. Impervious to Odors. You can spend a fortune on sanitation grade hose and your holding tank system will still stink, but it won’t if you use PVC pipe. (http://www.morganscloud.com/2008/05/18/pvc-pipe/)

- PVC is corrosion resistant, lighter, its neater looking and maintenance free (at $6, its a throw away item).

- Never use PVC for anything on a boat where if it breaks, it could sink your boat. PVC is just not strong enough. One good kick, slip or if something lands on it, it could break. The cheap price is not worth the risk of sinking your boat. For non-critical applications that cannot sink your boat, then no problem. The problem is, most of those hoses running around your boat below the waterline do have the potential of sinking your boat. For non-critical piping you may want to use ABS instead of PVC. (http://www.cruisersforum.com/forums/f115/home-depot-plumbing-fittings-just-bad-or-really-bad-19659.html)

- Your boat won’t pass a survey if it has PVC below waterline…HOWEVER…Upon further reading – I notice that Steve Dashew in his Encyclopedia (1997 Edition pg. 802) has no qualms about using them. Also Saint Nigel – patron saint of all things yacht like – uses PVC pipes (Boatowners Mechanical and Electrical Manual, 2nd Ed. pg 361) Thus its very odd that someone stated that PVC pipes and fittings wont pass survey now – one possibility could be that my books are pretty old and out of date and standards have since changed.Given that Dashew and Calder are unopposed to the idea of PVC pipes and fittings, perhaps it wasn’t such a stupid idea after all. Although, in their day, all this stuff was made in the USA where quality and standards are always assured. Nowadays, all this stuff is made in China only. The quality of material and construction of anything from the PRC is always questionable. In the end thats what made me think twice. (http://www.cruisersforum.com/forums/f115/home-depot-plumbing-fittings-just-bad-or-really-bad-19659.html)

- I looked at the PVC valves there, if you check they have steel parts in them a small ring (http://www.cruisersforum.com/forums/f115/home-depot-plumbing-fittings-just-bad-or-really-bad-19659.html)

- I believe that “Marelon” is a UV stabilized Fibreglass Reinforced Nylon polymer. (http://www.cruisersforum.com/forums/f115/home-depot-plumbing-fittings-just-bad-or-really-bad-19659.html)

- Maine Cat uses Schedule 40 pipe between the heads and the holding tank on the 41. If Dick Vermeulen approves something, its gospel in my book (http://www.cruisersforum.com/forums/f115/home-depot-plumbing-fittings-just-bad-or-really-bad-19659.html)

- There is nothing wrong with using plastic fittings and valves as long as they are protected (just as any small diameter pipeword should be even if metal). Contrary to the responses from some others I take it that you are not talking about using rigid PVC pipe, just fittings and valves.I would recommend though that if it is below the water line you use threaded engineering polypropylene fittings which are good for typically close to 250 psi (there are also fibre reinforced ones but are harder to find) and plastic engineering ball valves. These are normally available from any plumbers merchant – I am not familiar with what USA Home Depots stock, but may be available from them too. Above the waterline (say at least 200mm above) then rigid PVC is fine and often the material of preference in high quality builds (eg as Sandy points out, for black water).In our own boat we have the polypropylene fittings and plastic ball valves (it was a professional custom build) below the water line for the seawater distribution headers after the seacocks with no problems at all. They are located so that they are protected from accidental physical damage. Our engine exhaust, which discharges above the waterline, is an example of something we have fabricated from rigid PVC pipe. From the surveys I have seen the greatest cause of flooding accidents in boats is by far from failed metal pipework (ie after the seacocks) so metal solutions are not free from their own problems. Plastics will last the life of the boat, they (like any small diameter fittings and pipework whatever the material) just need to be protected from physical damage.Regarding passing survey for commercial vessels, in the jurisdiction I work in plastics are accepted by local rules as it has been in vessels built to the rules of classification societies that I have been involved with. The usual limitations just being that the material is suitable for the task, including suitability for the fire rating of the compartment they are in, and properly installed for the service. Personally, I believe that would exclude the use of rigid PVC below the waterline in seawater services – it does not exclude other plastics however. (http://www.cruisersforum.com/forums/f115/home-depot-plumbing-fittings-just-bad-or-really-bad-19659.html)

- PVC plumbing is often used on larger yachts, for domestic water, grey and black water. It must be installed where there can be no flex/risk of bending. Not normally seen on smaller boats because the runs are so short. No problem with PVC. Just dont use it for raw water and connections for under the waterline. (http://www.cruisersforum.com/forums/f115/home-depot-plumbing-fittings-just-bad-or-really-bad-19659.html)

- Those nylon barbs can be snapped of fairly easily and should be left to domestic water or sanitation use not bellow waterline applications..I personally, on my own boat, snapped a thru-hull fitting when a spare alternator hit the valve in rough seas. No PVC for me and I now only install through bolted seacocks and not just a valve on a thru-hull.Brass, nylon and PVC are fine for domestic h2o or sanitation plumbing as your poop and drinking water won’t sink your boat (http://www.cruisersforum.com/forums/f115/home-depot-plumbing-fittings-just-bad-or-really-bad-19659.html)

- I’ve got no problem WHAT SO EVER in using sch 40 or 80 PVC pipe or fittings on my boat, the QA/QC is probably better than 80% no 90% of the garbage hoses that I see on many boats.PVC ball valves vary greatly in quality. I’ve got no problem using good ones, however my sea cocks are bronze (http://www.cruisersforum.com/forums/f115/home-depot-plumbing-fittings-just-bad-or-really-bad-19659.html)

- I used 1.5″ sched 40 PVC pipe in my sanitation plumbing to my holding tank and a portion is below the water line…YIKES! I’ve had bad experiences with so-called marine sanitation hose. It degrades fairly quickly and the “stink” goes right through it. I was leery of using PVC so I did some “rube goldberg” testing to gauge its brittleness. I dropped a 35lb iron dumbell on the pipe from a height of 5ft on a concrete driveway and couldn’t break or crack the pipe….for unplasticised PVC eg rigid Sched 40 & 80, it is subject to embrittlement as the temperature drops and that should be kept in mind for below waterline use. At -10C (14F) its impact strength is typically around 1/4 of that at 20C (68F) but the drop in impact strength from that at 20C and that at the freezing point of water is steep with most occuring between 20C and 10C (50F) – at 10C impact strength is typically nearly half that at 20C but even that reduction is not a problem in use as these are typical working temperatures. As you say though unplasticised PVC Sched 80 & 40 is very resistant to impact so is still so at the lower temperatures but is probably of concern enough to be wary about its use below the waterline. (http://www.cruisersforum.com/forums/f115/home-depot-plumbing-fittings-just-bad-or-really-bad-19659.html)

- Wouldn’t copper or rigid PVC pipe be better than vinyl hose? Generally speaking, no. Rigid PVC (or rigid copper) piping is far more difficult to install than hose. Every piece must be cut to a precise length, and every change in direction requires an elbow and two connections – potential leak sources. Even when the run is straight, the restricted spaces on a boat are likely to prevent installing a long length of pipe as a single piece. And unlike houses, the “walls” in a boat are not straight and square, so unless the pipe has considerable flexibility, it will “bridge” the hull rather than lie against it. Given that the pipe is sure to pass through stowage areas, rigid PVC is at greater risk of damage than hose from a shift of the other contents of the locker. (This Old Boat, p. 316)

Comment Form