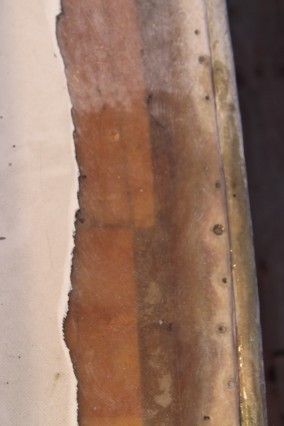

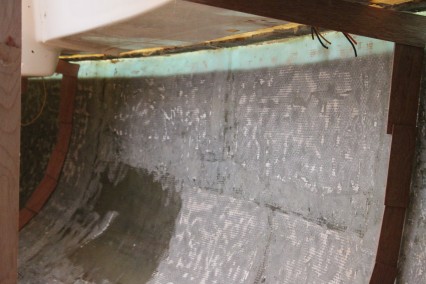

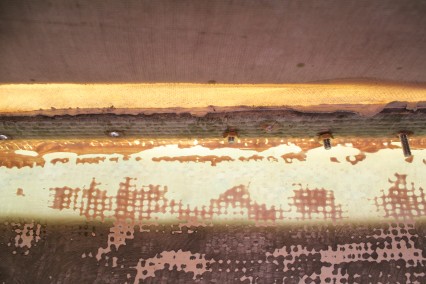

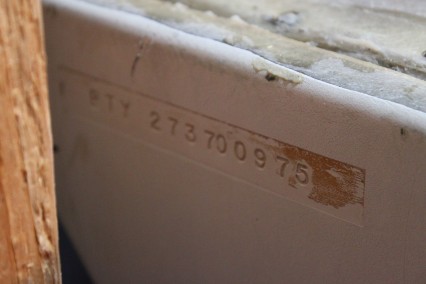

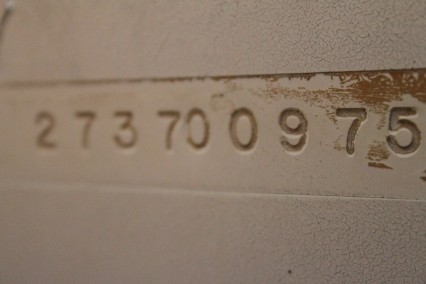

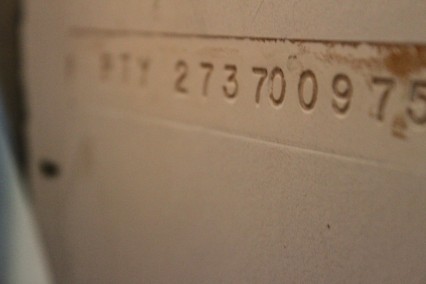

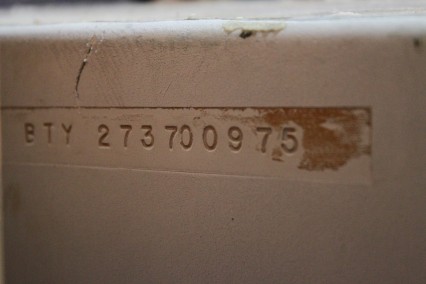

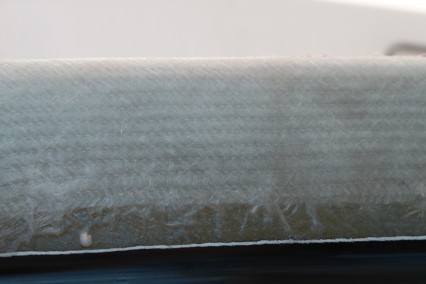

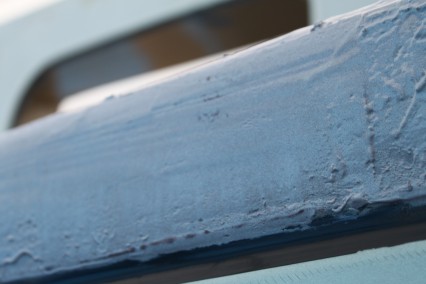

Hull to Deck Joint

Image Gallery

Research

- Under bending loads, the deck is heavily stressed because it functions as the top flange of the hull girder…the deck most posses strength the same order of magnitude as the topsides of the hull along the deck edge. Deck strength should not be compromised by hatch or cockpit openings that are excessive in number or in size. This is particularly important amidships and near the deck edge. (Desirable and Undesirable Characteristics of Offshore Yachts, p. 95)

- The hull/deck joint can be a weak point in fiberglass hulls. Mechanical fastening alone is often not adequate…Fiberglass bonding across the inside of this joint can be used to bring it up to the same strength as the adjoining hull and deck surfaces….Obviously, the hull-to-deck joint is critical. if it fails, not only will a lot of ocean be let in but structural integrity of the entire hull will be compromised. In fiberglass boats, the joint should be composed of flanges secured by many bolts and much reinforcement. (Desirable and Undesirable Characteristics of Offshore Yachts, p. 98, 106)

- The deck has six functions that must be satisfied for safety, comfort, and efficiency: (Desirable and Undesirable Characteristics of Offshore Yachts, p. 105)

- It should contribute to the overall strength and stiffness of the hull and rig

- For safety, it should keep the ocean out.

- For comfort, it should keep drips and dollops out.

- It should be a good platform for boat-handling and navigation gear.

- It should provide a safe, comfortable working area for the crew and guests.

- It should provide good below-deck headroom, ventilation and access.

- The deck makes several major contributions to the boat’s overall strength and stiffness. First, it acts like the top flange of an I-beam, serving as the upper chord in the scheme of longitudinal strength. The deck resists the heavy longitudinal compression loads imposed by the downward thrust of the mast and the upward pull of the stays and sheets, which try to bend the yacht into the shape of a banana….The deck also serves the essential purpose of providing torsional stiffness to the hull, thereby converting heeling and twisting moments into righting moments and keeping the boat from changing shape under sailing load. (Desirable and Undesirable Characteristics of Offshore Yachts, p. 105 – 6)

Comment Form